With its online shop, wide range of production equipment and highly efficient material flow, De Cromvoirtse, a Netherlands-based steel wholesaler and contract manufacturer of sheet metal products, is well equipped to deal with the increasingly intense competition in its sector. In order to ensure fast deliveries to its customers, the manufacturer of semi-finished sheet metal products relies on automated storage equipment from KASTO. The UNILINE in-line storage system and UNITOWER B tower storage system ensure fast, damage-free and error-free material handling. These systems are automatically connected with three laser metalworking machines. A uniform KASTOlogic warehouse management system keeps perfect track of stocks and ensures smooth order processing.

Online shopping is on the rise – not only for clothing, books and electronic goods, but also in businesses like the steel trade. Manufacturers are increasingly ordering materials with a simple mouse click. This saves time and cuts costs, because it makes comparison of different offers very easy. But the increased competition poses a challenge to vendors. To be successful, they must not only have a broad range of products and attractive prices, they must be able to make fast deliveries and provide a comprehensive array of services.

The Dutch steel wholesaler and contract manufacturer of sheet metal products De Cromvoirtse spotted this trend very early and took appropriate steps. “Snel metaal op maat” (Metal – made to measure, fast) is the motto of this company with headquarters in the town of Oisterwijk, near Tilburg. Founded in 1982, it specialises in partially finished goods, which it produces in small batches. De Cromvoirtse has operated an online portal since 2008. Today it gets about 70 percent of its orders through this channel. Customers can use it to upload drawings and various specifications, and within two minutes they receive an automatically calculated quotation for production of the component in question.

Small batch sizes and short delivery times

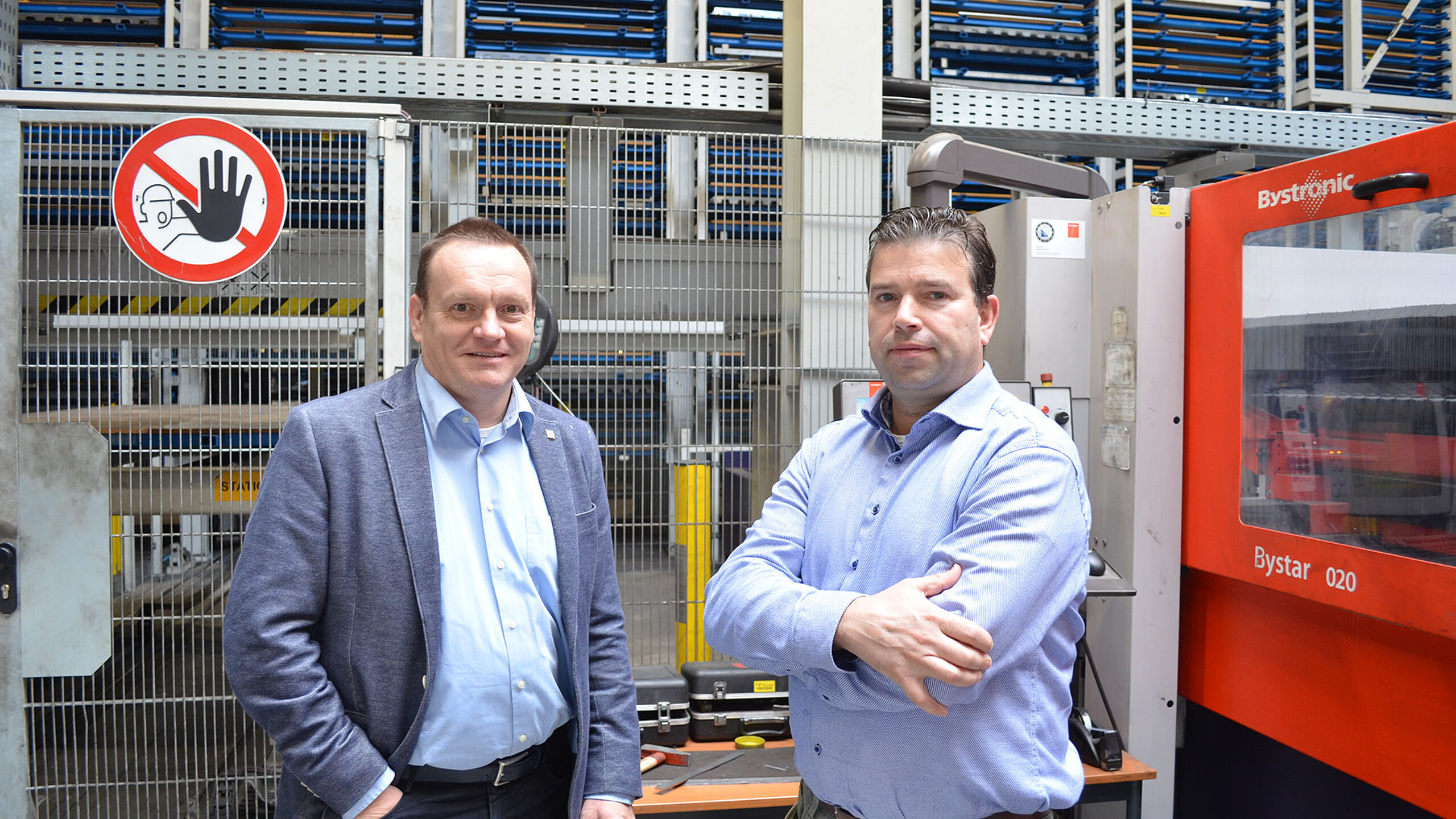

De Cromvoirtse’s manufacturing capacity includes a number of laser cutting machines and folding presses. About 90 percent of its products are steel, inox or aluminium sheet metal parts; the remainder are pipes and sections. “Most of our roughly 1,200 customers are small and medium-sized companies, like agricultural machine manufacturers, car body makers and machine builders,” says Janwillem Verschuuren, one of the two managing directors. “For them it often doesn’t pay to buy machines of their own and hire expert personnel, because they only have small production runs.” De Cromvoirtse holds a strong position on the Dutch market as a manufacturer of custom-made parts in small quantities. It also enjoys a unique reputation for fast deliveries: “As a rule, we can deliver laser-cut parts in 24 to 48 hours; folded sheet metal parts can be supplied within a week,” says Verschuuren.

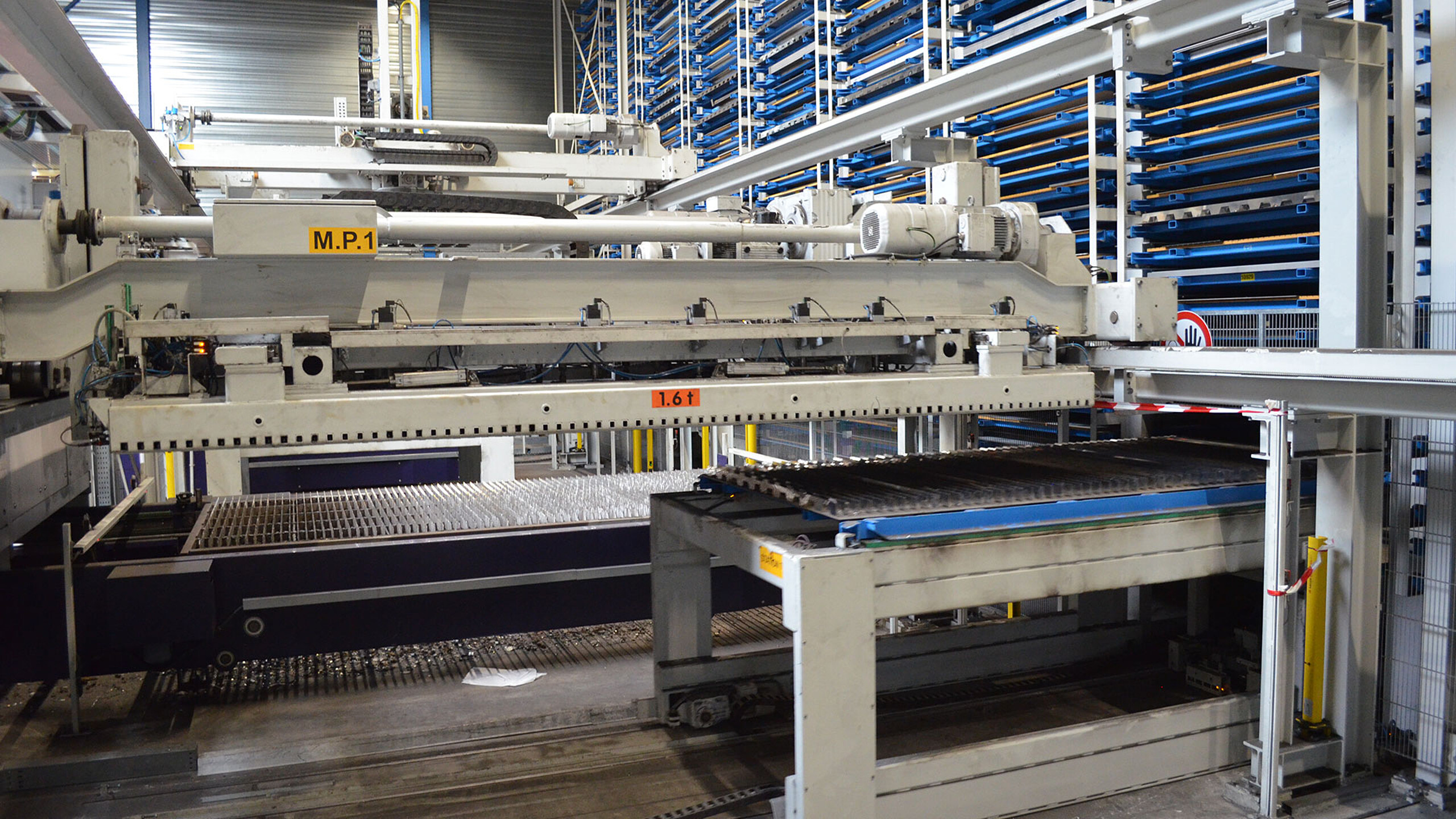

To serve the needs of its growing customer base reliably and quickly, De Cromvoirtse has not only automated its ordering process, it has also automated most of its production. Its metalworking machines operate around the clock, seven days a week – and on 1.5 days fully unattended. Large stocks are another big success factor. On average, 400 to 500 tonnes of material are kept in supply. The storage equipment is also state-of-the-art. A double-sided KASTO UNILINE in-line storage system with almost 1,000 storage locations has been in place since 2011, efficiently supplying sheet metal. It has special pallets for different materials and sizes, as well as for remnants. A gantry crane travels between the two rows of the facility, storing and retrieving items fully automatically as needed.

Cooperation to develop fresh designs

“Back when we had to invest in a new warehouse, our choice quickly fell on KASTO,” recalls Verschuuren. “Other manufacturers offered us standard solutions that were unsatisfactory, whereas KASTO worked with us right from the planning phase to develop new ideas for the design. They told us very clearly what would work and what wouldn’t.” For example, it was possible to seamlessly connect two flatbed laser cutting machines in a continuous material flow. For this purpose KASTO installed two manipulators at the output stations of the UNILINE storage system. Using vacuum suction units the manipulators lift sheets from storage, place them on the shuttle tables and then remove the finished parts and remnants.

“The KASTO solution permits fast, efficient and gentle handling of our various materials,” explains Ronnie van den Hurk, the other managing director at De Cromvoirtse. “The stacker crane is equipped with two pallet stations in order to shorten the cycle times. In this way we avoid empty runs. For each storage operation there is always a retrieval operation happening at the same time.” With its UNILINE facility De Cromvoirtse has substantially increased the capacity of its machines and shortened the throughput times.

Additional tower storage system for greater capacity

However, owing to the company’s booming online business and growing numbers of orders, even this system reached its limits after a few years. In 2016, the steel wholesaler therefore again asked KASTO how to increase the performance of its storage facility. “Our first thought was to add a second gantry crane to the existing UNILINE system,” says Klaus Seifermann, head of the sales team. “But this reconfiguration would have interfered with our operations and was therefore out of the question.” So KASTO worked out an alternative solution. It installed a separate UNITOWER B tower storage system next to the existing in-line storage system, in this way providing additional capacity.

The compact storage system consists of a double tower. With its height of 8.5 metres and small footprint it has space for almost 80 pallets, each of which can hold sheets measuring up to 3,000 x 1,500 mm. A gantry crane with a central crossbeam handles the load carriers. In this way it is not necessary to move the entire stock, but only the pallet in question. This ensures fast access times, and the high-efficiency lifting gear offers significant energy savings. The UNITOWER is connected to the existing UNILINE storage system for maximum flexibility. A bridge with a longitudinal carriage riding on a rail connects the two systems at the top. “In this way we can move pallets automatically from one area of the storage facility to another without losing valuable space down below,” explains van den Hurk.

Connecting machines of other manufacturers

An additional laser cutting machine is also connected to the UNITOWER system. Loading and unloading are performed by a fully automatic handling system from a third-party supplier. Using various grippers it can handle whole sheets as well as cut parts and remnants. “This increases our productivity and gives us greater flexibility,” says Verschuuren. A special advantage of the KASTO solution is that it can easily be integrated into the metalworking machinery of other manufacturers. “Thus we are not dependent on a single manufacturer, as we would be with many other systems,” explains Verschuuren. “We can use the machines that are most suitable for the given requirements.”

KASTO installed the tower storage system in just a few weeks without interrupting operations. “We didn’t want the work to cause delays in deliveries – and we succeeded,” says Verschuuren. Both the new and the existing system are controlled by KASTO’s warehouse management system, KASTOlogic. “We programmed the software to treat the two areas as a single connected storage system,” explains team leader Seifermann. “This makes it easier to operate and increases the stock transparency.” In addition, the warehouse management system is connected with the company’s ERP system, ensuring a consistent data flow and smooth order processing. “For us it was – and still is – a great relief to be able to consult KASTO regarding both hardware and software,” adds Verschuuren.

Fast troubleshooting by remote maintenance

Since many of De Cromvoirtse’s machines run unattended, they are equipped with cameras. In an emergency, malfunctions are reported directly to employees’ smartphones so that they can react swiftly. In addition, both the UNILINE and the UNITOWER system can be monitored remotely. “If necessary, KASTO’s experts can access the facility online from Germany and rectify any problems,” explains van den Hurk. But he notes that this has rarely been necessary. “The facility is perfectly reliable, and thanks to training of our employees by KASTO, operator errors are also very uncommon.”

De Cromvoirtse’s two managing directors are highly satisfied with their choice of the German storage technology specialist. “KASTO gave us optimum support in our latest project, as it did from the very start of our cooperation,” says Verschuuren. “It listened to our requirements and presented an ideal solution.” “We’ve achieved yet another big increase in productivity, while also making work easier for our employees,” adds van den Hurk. The steel company’s customers continue to benefit from short delivery times. “In fact, our facility has become so interesting to other companies that we get frequent requests from the Netherlands and abroad for a chance to have a look,” says Verschuuren. “This is further proof that KASTO has helped us to implement a system that you don’t see every day.”