Automated sawing. Clever material handling. For efficient metalworking.

Review: KASTO at EMO 2025

Complete solutions for the entire process chain: sawing, storage, material handling – but please make it smart, automated and efficient! From 22 to 26 September, KASTO presented live at EMO in Hanover how complete process chains in metal processing can be optimised. Many thanks to all visitors for their time and the interesting discussions at our stand.

Here you will find an overview of our innovative solutions – from powerful saws to award-winning complete automation.

Award-winning complete solution

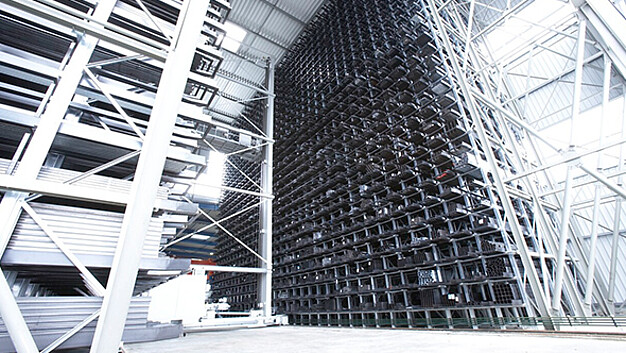

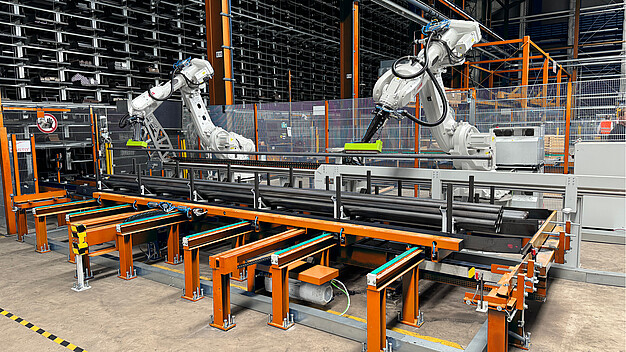

KASTOsort tower

Flexible sorting and storage technology in the smallest of spaces

Sawing, sorting and storage in one system: The KASTOsort tower combines maximum function in a minimum of space - ideal for unmanned processing in 24/7 operation. Whether as a stand-alone solution or in combination with high-performance saws such as the KASTOtec, parts are sorted to order and stored precisely. With intelligent control, app connection and optional AGV interface, your production is fit for the future.

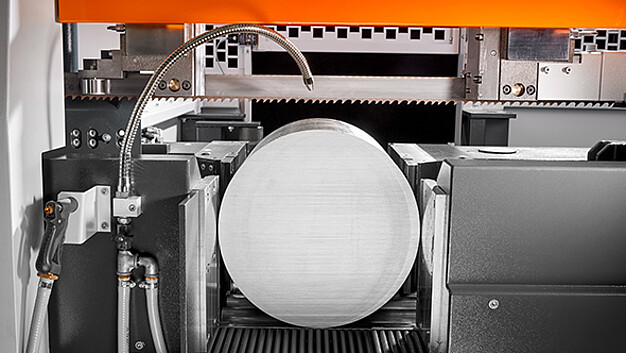

Automatic high-performance bandsaw KASTOtec

The power pack for the highest demands

Maximum precision, even with difficult-to-cut materials: The KASTOtec was developed for maximum cutting performance in 3-shift operation. With optimum support for bi-metal and carbide technologies, it ensures high productivity with minimum non-productive times - economical, robust and powerful. Maximum sawing performance for demanding applications.

Fully automatic bandsaw KASTOwin

The power professional for continuous operation

The KASTOwin is the perfect partner for series and production cutting in pipe, profile and solid materials. From the turn of the year with the new ProControl control generation - including ‘Simple Mode’ and many smart features. These will be presented for the first time at EMO. Even more intelligent, user-friendly and efficient.

Tilting frame bandsaw KASTOmicut

The all-rounder for your workshop

The KASTOmicut impresses with semi-automatic or fully automatic operation, precise mitre cuts from -45° to +60° and a sturdy design. Ideal for pipe, profile and solid material - with infinitely variable cutting speed for maximum flexibility. Compact precision for flexible applications.

Smart Sawing

Precision, efficiency and progress combined

With smart technologies and networked solutions, KASTO takes sawing to a new level - for maximum productivity and efficiency.

Experience and innovation come together in KASTO's intelligent sawing solutions: sensors, data analysis and intelligent assistance systems ensure optimised cutting strategies and increased productivity. Networked machines and cloud connections create full transparency - for greater efficiency and lower costs.

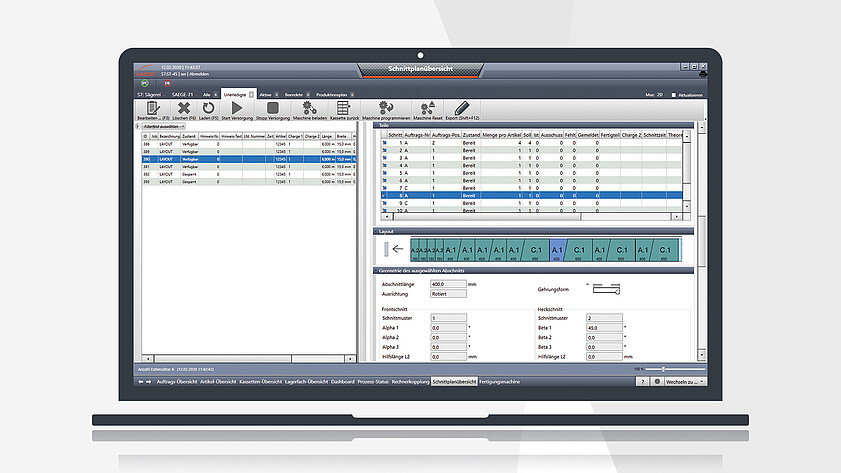

NEW generation KASTO control

New control generation for more convenience, more overview, more productivity: From the new generation onwards, the KASTO control system can be operated flexibly via tablet or PC using a browser and offers many great features, including ‘Simple Mode’, cutting plan function and optimised diagnostics and help options. Presented for the first time at the trade fair!

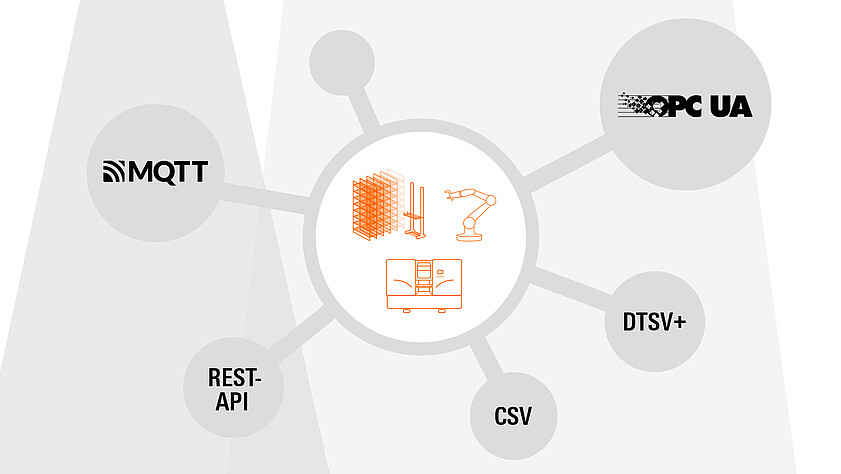

KASTOlink

Networked intelligence for optimised processes: KASTOlink creates seamless interfaces to your systems - from OPC UA and MQTT to the REST API.

KASTOrespond

Optimisation of the feed rate during sawing: KASTOrespond analyses your sawing parameters in real time, reacts independently to changes and thus ensures shorter cutting times and longer tool life.

KASTOapp

Full control in the palm of your hand: KASTOapp controls and monitors your saws anytime, anywhere. Intelligent notifications and real-time data make you more flexible than ever before.

KASTOoptisaw

Optimisation at the touch of a button: KASTOoptisaw automatically creates the best cutting patterns and reduces material waste. For greater efficiency and maximum cost-effectiveness in your production.

Experience technology live – directly at our customers' premises

Experience metal saws combined with suitable material handling or storage up close: our individual reference visits give you the opportunity to experience KASTO solutions in live operation. Efficient, automated and future-oriented. Even after the trade fair, this is possible at any time – tailored to your wishes and requirements across regions.

See for yourself with real projects and best practices at first hand.

Press area

From the start of the trade fair, you will find everything you need for your reporting here: current press releases, technical articles and printable images of our trade fair highlights - from the new generation of KASTO control units to the award-winning KASTOsort tower.

We will also be happy to send you our press releases in time for the start of the trade fair. Or would you like to meet us in person at the EMO? Please feel free to make an appointment with us.