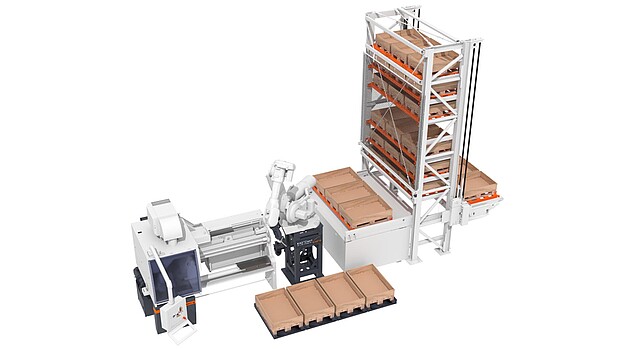

KASTOsort tower

| Product group: | Storage, Saw |

|---|---|

| Material shape: | Bar |

| Product type: | KASTOsort tower, Robotics, Sorting |

The maximum production in the smallest space

The KASTOsort tower automates the sawing and storage process with a space-saving system for processing, including sorting that works 24/7.

The new KASTOsort tower offers a fully automated solution for metal processing companies. It can be used as a highly productive complete solution or to supplement a KASTOvariospeed or KASTOtec with or without a KASTOsort robot. For an efficient process, the parts must be sorted by order after sawing and handling and placed in appropriate boxes. Previously, a container carousel on which the robot could place and fill the respective boxes independently was one of the solutions provided. This is a simple and cost-effective way of buffering manageable quantities of material.

Benefits at a glance

- 24/7 unstaffed operation thanks to standalone complete solution

- High storage density in minimal space

- Flexible and time-independent collection of pallets

- ProControl ensures fast, error-free workflows

- Seamless tracking thanks to storage management via the KASTOlogic mobile app

- Connection to customer-specific AGVs possible

The KASTOsort tower was recognised for its innovation and outstanding customer benefits at the "Product of the Year 2024" awards from INDUSTRIAL PRODUCTION and materialfluss.

1st place in materialfluss in the handling, assembly and production category

2nd place in INDUSTRIAL PRODUCTION in the picking technology category