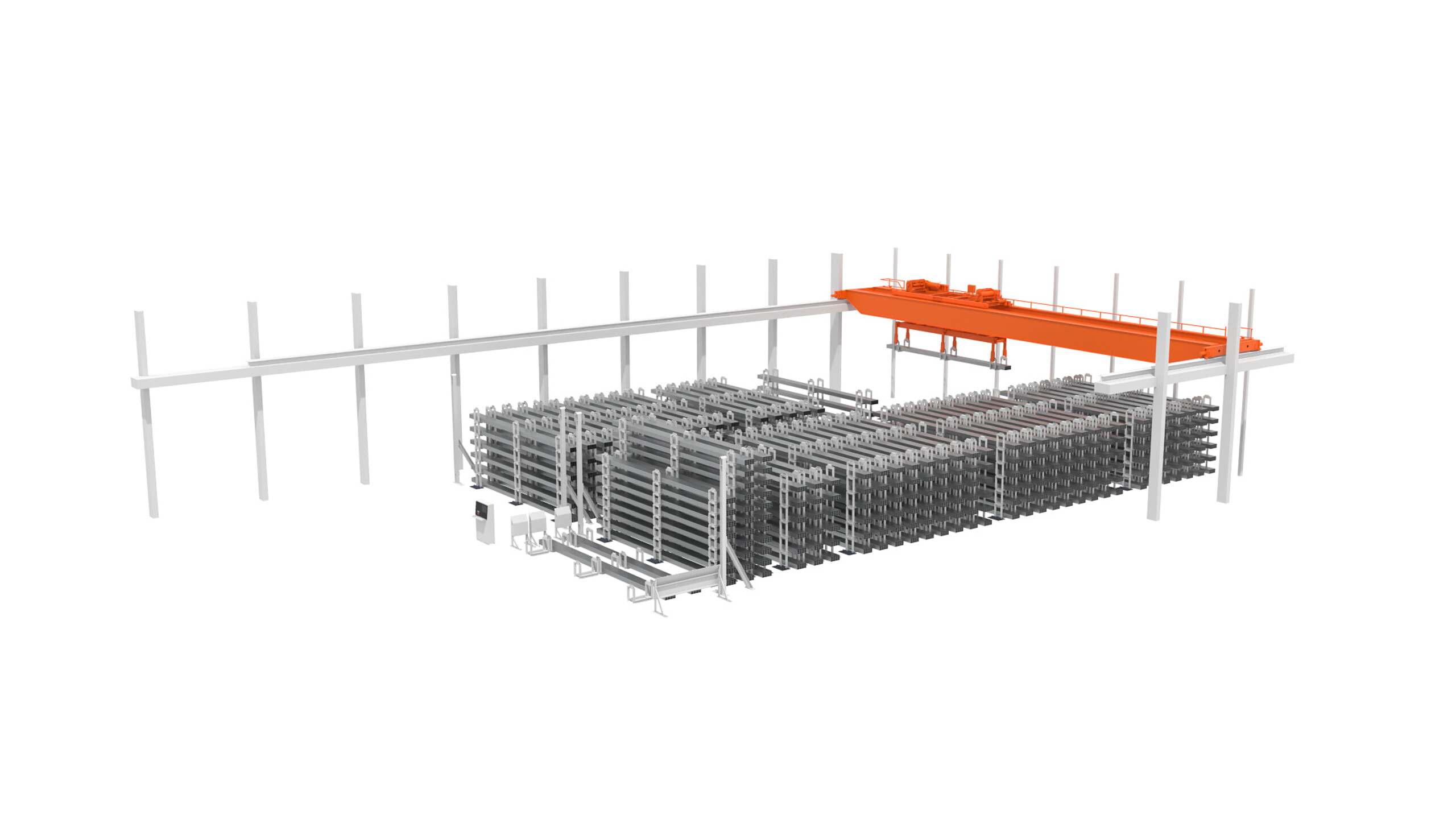

KASTOcenter

| Type: | Bar storage |

|---|---|

| Storage Type: | Sawing center |

| Loading per storage: | 0.5 t - 5 t / 1100 lbs - 11000 lbs |

| Storage length: | 3 m - 12 m / 10 ft - 39 ft |

| Storage size: | 50 - 9999 Locations |

| Integrated saw possible: | Yes |

Fully automatic and unmanned sawing and storage

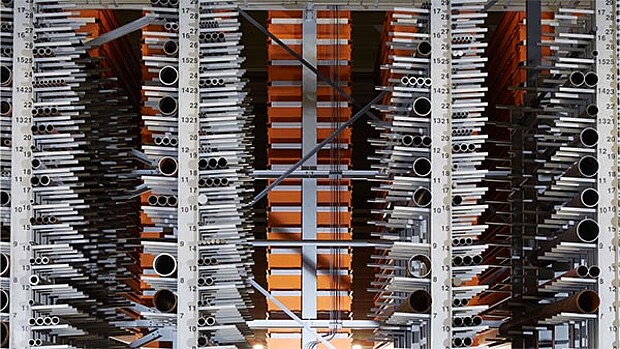

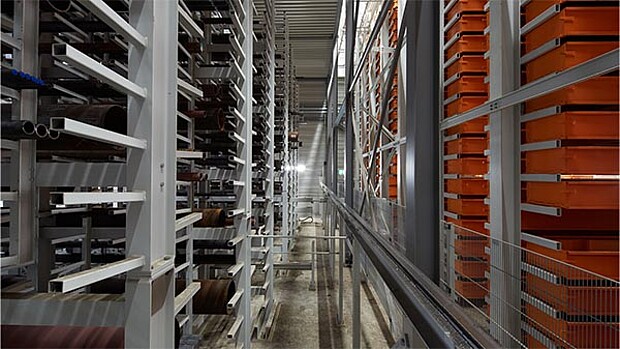

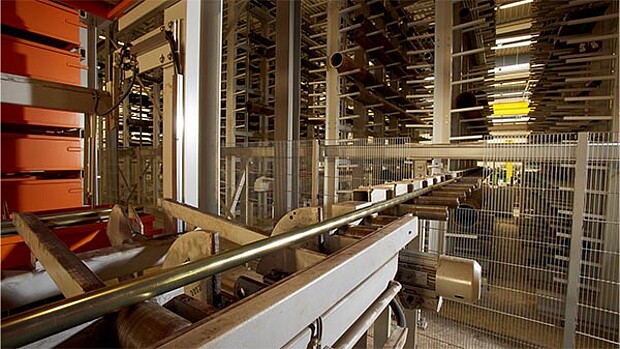

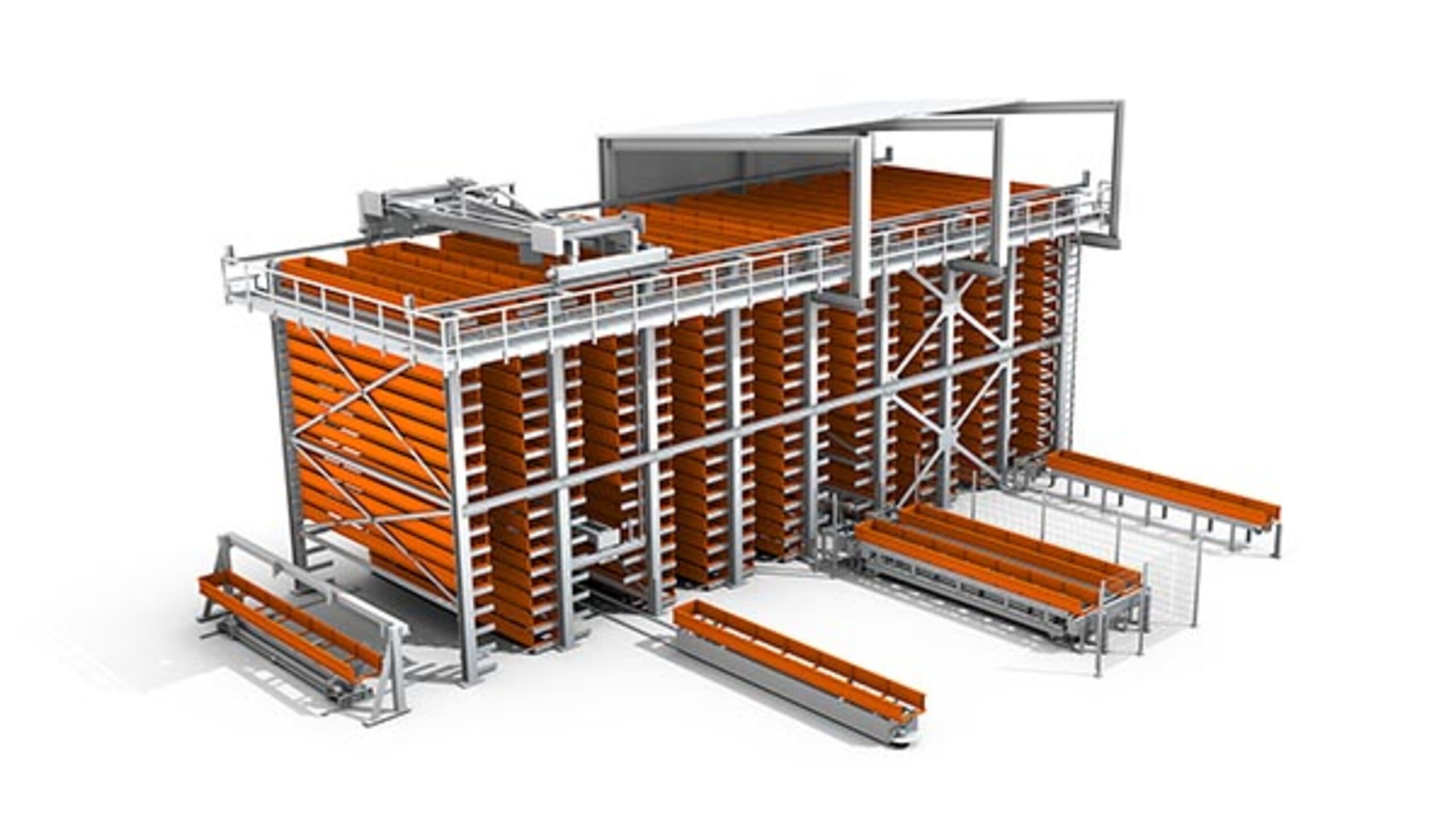

In a KASTO Sawing Center, computer-controlled operating cranes feed a single bar, fully automatic, to an integrated CNC-saw and automatically restore the remnants. A storage computer keeps inventory up-to-date. KASTO offers this flexible manufacturing system for the sawing department complete with storage system, saw, control and service as a one-source supplier!

Result: Highest reliability and minimum idle times due to perfectly fine-tuned individual components. And such a sawing center accomplishes as much as 3 to 7 individual saws!

Your benefits at a glance

- The specially formed KASTO loading platform removes and transports exactly one rod from the cantilever compartments

- Fully automatic bar handling

- The integrated saw is supplied with material via the operating gantry cranes, which are controlled by the KASTO Warehouse Management System

- Maximum reliability and minimal non-productive times thanks to perfectly matched individual components

- Combination of single rod and cassette storage possible

Technical Data

| Loading per storage space | 0,5 - 5 t | 1100 - 11000 lbs |

| Economic storage size | from 50 storage locations | from 50 storage locations |

| Storage lengths | 3 - 12 m | 10 - 39 ft |

| Economic system height | 3 - 10 m | 10 - 33 ft |

| Self-supporting construction possible | no | no |

| Number of accesses per hour (per OGC) | 5 - 20 | 5 - 20 |

| Semi-integrated sawing machines possible | yes | yes |

| Fully integrated sawing machines possible | yes | yes |