KASTO storage systems: Modern storage technology for bar and sheet metal

Whether for long goods or sheet metal, with our different storage types and sizes we meet your individual needs.

KASTO storage systems are used in various industries, such as mechanical engineering, window construction, steel trade and in the area of sheet metal processing.

Whether providing metals, steel or sheet metal to processing machines or for order picking, the areas of application are as versatile as the stored goods themselves. This ranges from bar materials, profiles, cassettes and pallets to sheet metal packages.

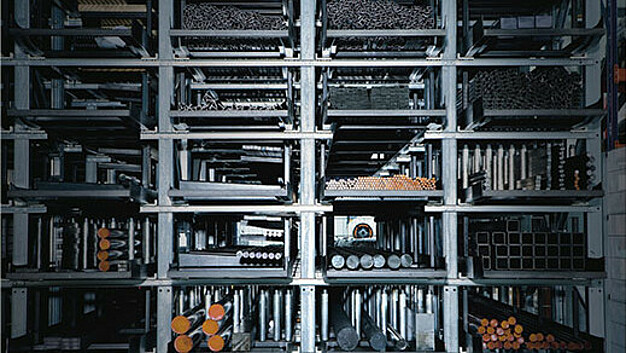

Bar storage systems

Long goods storage for bars, tubes, profiles and beams that can be adapted to individual needs. Use storage space economically and ensure effective material flow in production and trade.

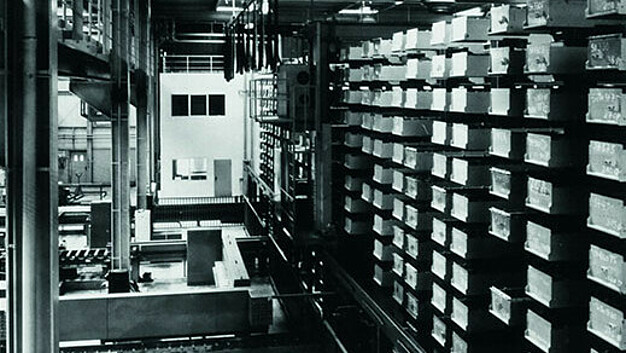

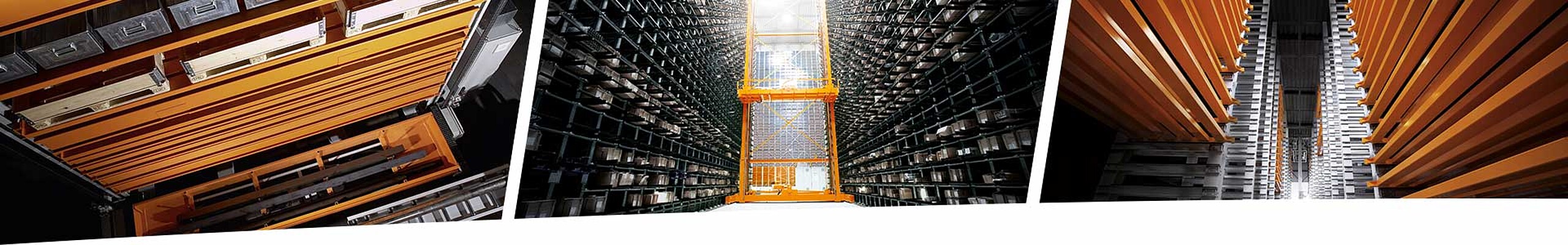

Sheet metal storage systems

Sheet metal storage systems for all tasks, storage quantities and handling speeds. KASTO sheet metal storage systems allow efficient storage for heavy and thin sheets in all dimensions as sheet packs or sheets.

Whether fully automated high rack or manual storage systems, the Warehouse Management System (WMS) Software Suite KASTOlogic supports your work processes and helps organise them efficiently. Thanks to the digitalisation of the order picking processes, you increase their safety and flexibility.

A graphic user-friendly interface, designed based on a consistent operating philosophy covering simple controls through to job processing, supports the operator in daily warehousing tasks.

Integrated algorithms continuously generate statistics, enabling the detection of bottlenecks in the automated storage system. The system’s full potential is utilised by making adjustments to the material flow strategies. A modern 3D simulation checks and assesses potential system modifications.

KASTOlogic enables the integration of sawing machines and material handling equipment, such as robotics, bar singling devices, roller conveyors manufactured by KASTO or by other leading manufacturers. Integrated order and production management provides an improved overview of the capacity of the connected production machinery, focusing on the fields of sawing, stamping and laser cutting.

Capacity, running times and wear in the warehouse system are improved through the established and proven and individually adjustable algorithms as well as intelligent warehouse strategies.