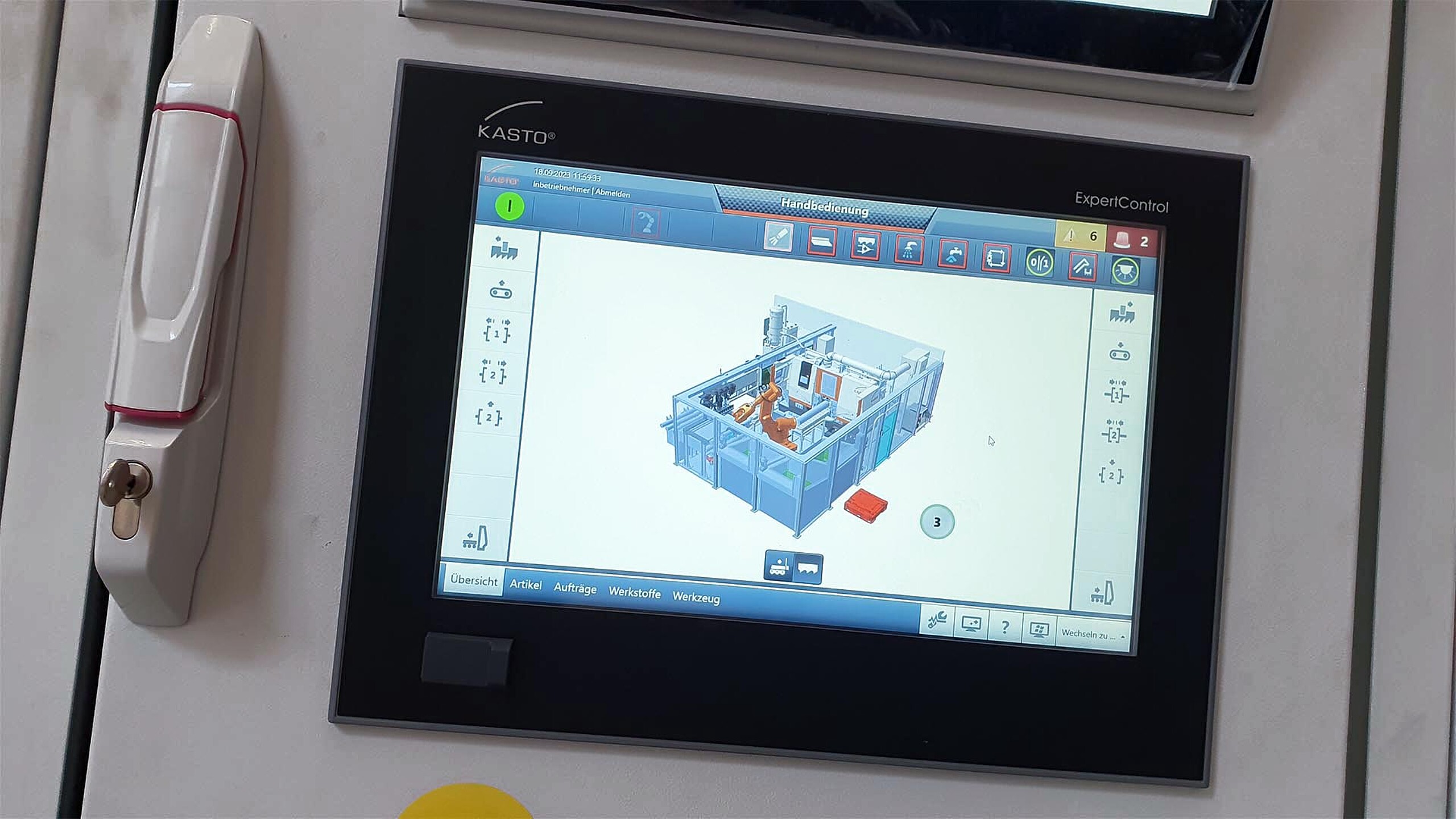

Discover versatility: Metal saws from KASTO

The KASTO saw programme is as versatile as the tasks in the field of metal sawing, therefore you will find hacksaws, band saws and circular saws in our assortment..

KASTO stands for quality and durability. This is reflected in all our products, from the universal workshop saw for occasional cuts to the powerful fully automatic machine for industry.

Whether for straight cuts or mitre cuts, sawing bar materials, panels or profiles, with us you will find the right saw for your application. We will be happy to advise you on the choice of suitable machines for sawing metal, steel or aluminium.

![[Translate to English:] KASTO Metall-Bügelsägen [Translate to English:] KASTO Bügelsäge für gelegentliches Sägen von Metall](/fileadmin/_processed_/1/d/csm_KASTO_Buegelsaegen_314a81cc72.jpg)

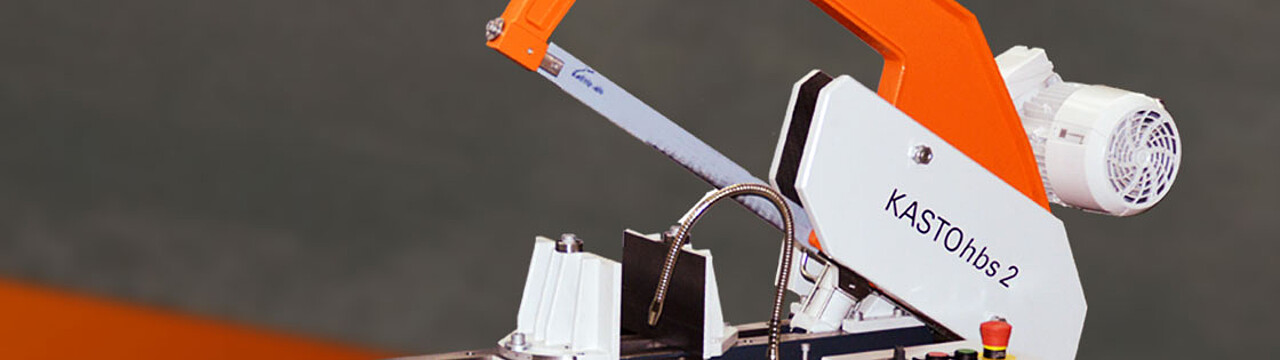

Hack saws

The universal KASTO hack saws are for occasional sawing of metal.

![[Translate to English:] KASTO Metall-Bandsägen [Translate to English:] Bandsägemaschine von KASTO für Geradschnitt](/fileadmin/_processed_/e/3/csm_KASTO_Bandsaegen_a61db3330f.jpg)

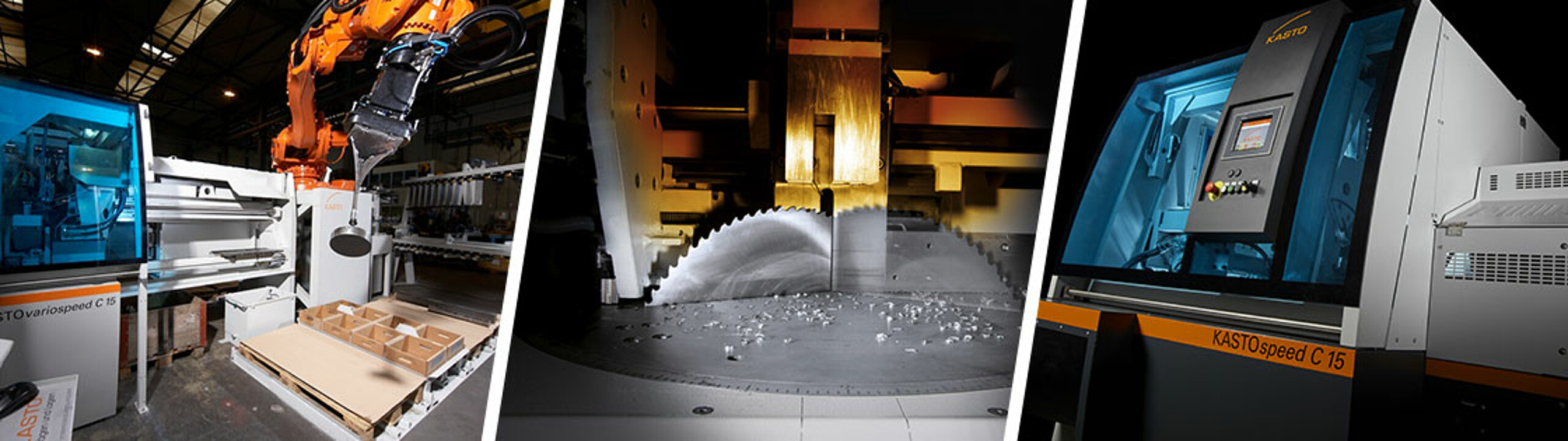

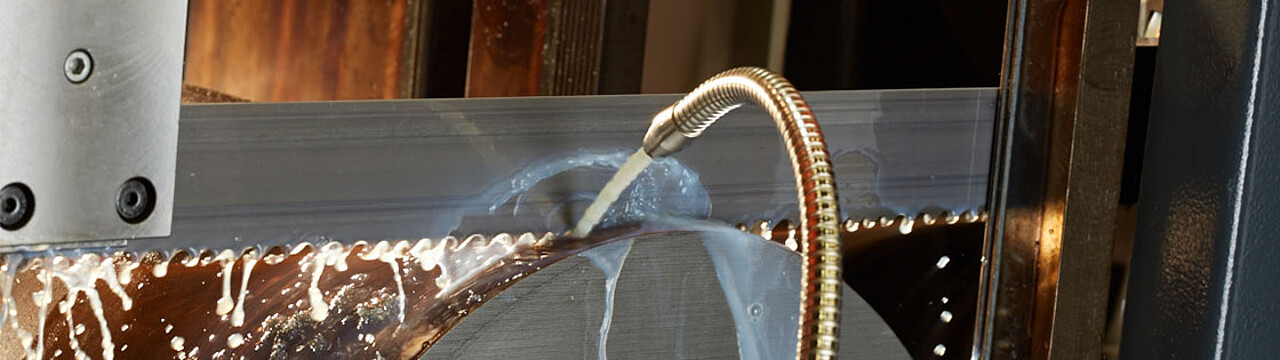

Bandsaws

KASTO bandsaws are universally applicable and very efficient.

![[Translate to English:] KASTO Metall-Kreissägen [Translate to English:] KASTO Kreissägen für Massenschnitt](/fileadmin/_processed_/0/5/csm_KASTO_Kreissaegen_f9782d67bf.jpg)

Circular saws

Efficient and powerful circular saws for large-scale production.

KASTO distinguishes itself through its broad range of sawing machines for the workshop – designed especially for small and mid-sized companies. Machines providing maximum reliability and precision are available even for occasional or small metal cutting jobs. That is why KASTO's complete know-how and experience goes into each workshop saw.

KASTO has the right solution for all of your applications. Dual column-guided, fully automatic high-performance bandsaws for mass-cutting in manufacturing and production as well as carbide metal production bandsaw systems for the industrial and automotive sectors and steel trade industry. Our fully automatic sawing systems with automated material feed and cut-piece sorting units enable multi-shift operations with low personnel requirements. We also offer a solution for additive manufacturing.

Do you need an efficient and robust sawing machine for your production? KASTO provides high-performance circular sawing machines for efficient processing of bar stock with HSS and carbide tools for tool steels and materials that are difficult-to-cut such as titanium, Hastelloy, Inconel and many other for small and large cutting quantities.

The ideal sawing machine for creating various dimensional cuts from billets or plates, squared or flat materials: KASTO block and plate bandsaws designed for longitudinal sawing operations. This principle is perfectly suited for cutting blocks and plates, trimming plate layers as well as notching cuts.

The hacksaw method patented by KASTO is characterized by its bow-shaped, pushing and cutting movement. Until that time, hacksaws, in which the sawblade is clamped in a U-shaped bow, were painstakingly operated entirely by hand. However, for many companies, the machine-operated hacksaw simplified this cumbersome process while providing a considerable increase in performance. In 1952, KASTO presented a metal hacksaw for the first time at the trade fair in Hanover. Even today, smaller hacksaws are used for a broad range of tasks in workshops.

In 1975, KASTO expanded its sawing machine portfolio and the third method with the bandsaw machine. The continuous endless sawblade distinguishes this process. It enables an efficient and uninterruptable cut. Thanks to the thin sawblade, the material loss is significantly lower than that of the circular saw. KASTO offers a wide range of products, from workshop saws for making single cuts to powerful fully automatic machines for your demanding sawing tasks as well as high-performance bandsaw machines for the industrial machining of large blocks and plates.

Different materials such as iron, stainless steel, aluminum and increasing production requirements make other sawing methods necessary. To meet this challenge, in 1965, KASTO began producing circular sawing machines. The circular saw method is characterized, in particular, by the efficient processing of easy and difficult-to-cut materials. This method ensures that the higher industry and production demands can be fulfilled.

Testimonials saws

A strong partner for every sawing task

From titanium and superalloys to aluminum and even ancient meteorites: For the sawing service provider Metal Cutting Service (MCS), offering a wide range of cutting abilities is an integral part of its business model for its customers – so MCS needs powerful and robust sawing machines that can be easily adapted to varying requirements.

We calculate the cost per cut for you

Do you know your cost per cut? We are pleased to determine it for you in a personal call.

Run the saw check

Trust the experts. Let's do a "health check" by our Service.