KASTO at LogiMAT

24 to 26 March in Stuttgart | Hall 3, Stand D45

KASTO will demonstrate how to intelligently manage and handle heavy, cumbersome materials in storage systems and production at LogiMAT.

KASTO´s stand will highlight KASTOflow, which facilitates the physical movement and packaging of materials, alongside KASTOlogic mobile, a digital solution for product management and documentation. Together, these solutions create a seamless material flow that enhances both operational efficiency in storage systems and strategic planning within ERP systems.

Everything in sight – everything in motion

KASTOlogic mobile helps companies reduce long search times in their storage systems. This user-friendly app digitises the manual storage process, transforming mobile devices into smart assistants. As a result, employees always know the exact location and quantity of materials, which improves the efficiency of storage, retrieval, and order picking.

Employees are guided through each step of the process, from storage and provisioning to quality control. Control queries help prevent errors, ensure open orders are always visible, and allow all postings to be made directly from mobile devices. This approach saves time and effort while reducing inconvenient tasks.

KASTOlogic mobile live at LogiMAT

One of the main attractions for visitors at KASTO’s trade fair stand is a miniature storage system designed for bar stock. The shelves are equipped with barcodes, enabling attendees to see first-hand how easy it is to manage the posting of goods in and out of the system using the smart KASTOlogic mobile solution. A quick scan shows the materials stored in each shelf along with their respective quantities.

Intelligent material flow within the storage system

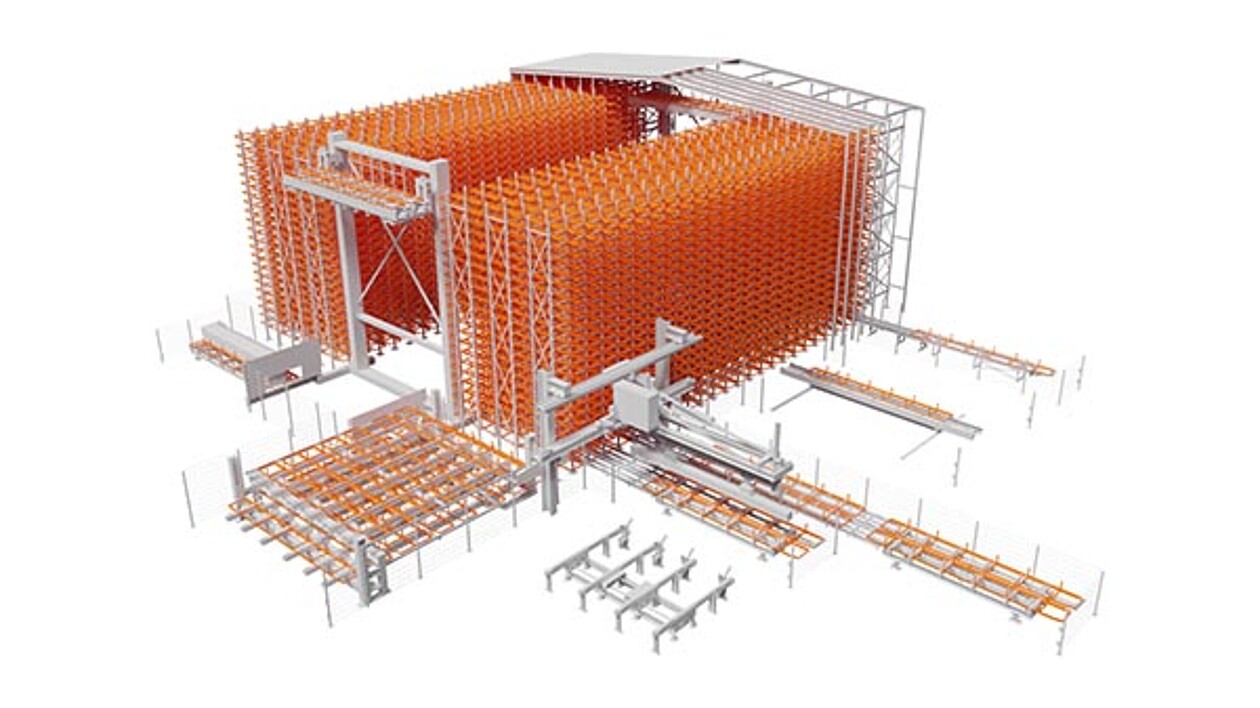

KASTO, an expert in storage technology, provides solutions for bar stock and sheet metal, offering options that range from single towers to custom-designed honeycomb storage systems. Their KASTOflow material handling solutions integrate seamlessly into the process chain, improving efficiency at every stage. When storage technology and pre-processing functions, such as sawing, operate together effectively, materials can flow through the facility without unnecessary detours.

These systems can incorporate coilers, buffers, lifts, sheet metal turnover devices, material buffer chains, and automated guided vehicle systems (AGVs) seamlessly, allowing for expansion without requiring manual intervention by operators. This results in reduced manual work, lower error rates, and significant time savings.